Basic design of GMB products

Quality and cost would be almost determined when the product is designed. GMB products are designed under the trade

mark "Global Management Business"

HIGH QUALITY PRODUCTS

QUICK DELIVERY

COMPETITIVE PRICE

BEST SERVICE

We GMB are making a continuous effort to guarantee the performance and quality based on our well-experienced knowledge.

Feature

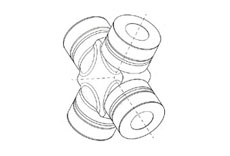

A universal joint is fitted between the driveshaft and the differential axle to transmit power through the axis of rotation.

Perfectly smooth rotation is required, in order to handle the constantly changing angles of the rear axle caused by

the vertical movement of uneven surfaces transmitted through the suspension system. In other words, a universal joint

efficiently transmits power through both fixed and fluctuating angles. Moreover, since the universal joint is lightweight and

compact with superior durability, it has proved to be a safe and positive product for power transfer in Automotive and

Industrial applications. In recent years, we have been working to develop and produce the press type bearing which

is aimed at improvement in intensity and durability and reduces cost further.

A universal joint is fitted between the driveshaft and the differential axle to transmit power through the axis of rotation.

Perfectly smooth rotation is required, in order to handle the constantly changing angles of the rear axle caused by

the vertical movement of uneven surfaces transmitted through the suspension system. In other words, a universal joint

efficiently transmits power through both fixed and fluctuating angles. Moreover, since the universal joint is lightweight and

compact with superior durability, it has proved to be a safe and positive product for power transfer in Automotive and

Industrial applications. In recent years, we have been working to develop and produce the press type bearing which

is aimed at improvement in intensity and durability and reduces cost further.

Structure

A universal joint has four needle roller bearings that provide the strength and life which is most important and both the

axes of the spider are inserted into two yokes. In the bearing, a seal is located to prevent dust, water, etc.

From ingress and to prevent grease egress. For heavy duty vehicles with high torque transmission, such as large size

vehicles and various industrial machine vehicles, a wing type (3 kinds: block, wing, delta) is used. Bolt-fastening

mechanism and key-way are incorporated to the bearing and a precise circle is on its back. By receiving the torque

through the key-way, even if a bolt is loosely tightened, the shearing stress does not apply to the bolt.

A universal joint has four needle roller bearings that provide the strength and life which is most important and both the

axes of the spider are inserted into two yokes. In the bearing, a seal is located to prevent dust, water, etc.

From ingress and to prevent grease egress. For heavy duty vehicles with high torque transmission, such as large size

vehicles and various industrial machine vehicles, a wing type (3 kinds: block, wing, delta) is used. Bolt-fastening

mechanism and key-way are incorporated to the bearing and a precise circle is on its back. By receiving the torque

through the key-way, even if a bolt is loosely tightened, the shearing stress does not apply to the bolt.

Feature

The steering joint is a type of universal joint which is used in a steering mechanism part. The main feature is that it

is miniature and lightweight since the rotation is slow and the torque requirement is small. Electrical drive steering

in recent prevalence requires more tensile strength.

The steering joint is a type of universal joint which is used in a steering mechanism part. The main feature is that it

is miniature and lightweight since the rotation is slow and the torque requirement is small. Electrical drive steering

in recent prevalence requires more tensile strength.

Structure

Same as the drive train universal joint in essence but it is made in much smaller design.

Feature

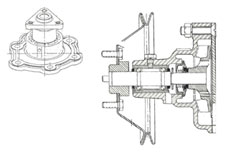

The engine for automobiles uses gasoline and light oil as fuel. They are evaporated first, then compressed and ignited

for explosions which give the engine the rotating power to crank shaft. In the engine, a gas explosion always occurs

during operation of the vehicle and the temperature of the gas increases up to 1500-2000 degrees. Therefore, in order

to prevent the siezure or meltdown of the engine by this temperature, there is the necessity of always maintaining the

proper temperature. Such equipment is called a cooling system and there are air cooling and water cooling technical options.

The positive circulation cooling device of water is almost exclusively used for automobiles at present in the industry.

Our water pump, which is the heart of the engine's cooling system, uses aluminum die casting and press-impeller to attain

the weight saving. Furthermore, we offer a long lasting water pump which minimizes power loss by using a consolidated

bearing and unitized mechanical seal with a low torque structure. Our water pump enhances fuel economy and contributes

to saving energy.

The engine for automobiles uses gasoline and light oil as fuel. They are evaporated first, then compressed and ignited

for explosions which give the engine the rotating power to crank shaft. In the engine, a gas explosion always occurs

during operation of the vehicle and the temperature of the gas increases up to 1500-2000 degrees. Therefore, in order

to prevent the siezure or meltdown of the engine by this temperature, there is the necessity of always maintaining the

proper temperature. Such equipment is called a cooling system and there are air cooling and water cooling technical options.

The positive circulation cooling device of water is almost exclusively used for automobiles at present in the industry.

Our water pump, which is the heart of the engine's cooling system, uses aluminum die casting and press-impeller to attain

the weight saving. Furthermore, we offer a long lasting water pump which minimizes power loss by using a consolidated

bearing and unitized mechanical seal with a low torque structure. Our water pump enhances fuel economy and contributes

to saving energy.

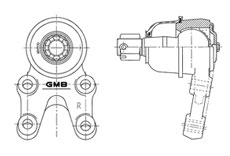

Structure

The cooling water that gets hot in the jacket is sent to the upper part of the radiator, then when it moves down the cooling pipe, the fan sucks the air from the outside and cools down the water so that it can be circulated in the jacket again and make the engine stay cool. In this positive circulation cooling mechanism the movement of the water pump is powered by the engine rotation through flange on the water pump bearing shaft. The impeller on the other end of bearing shaft runs and pushes the water by centrifugal force into the engine's water passage.

The cooling water that gets hot in the jacket is sent to the upper part of the radiator, then when it moves down the cooling pipe, the fan sucks the air from the outside and cools down the water so that it can be circulated in the jacket again and make the engine stay cool. In this positive circulation cooling mechanism the movement of the water pump is powered by the engine rotation through flange on the water pump bearing shaft. The impeller on the other end of bearing shaft runs and pushes the water by centrifugal force into the engine's water passage.

Feature

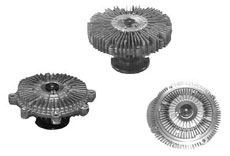

A fan clutch controls the

rotation of a fan because it reacts to the temperature of air which

passes through the radiator and has the role to maintain the heat

balance of an engine cooling system at the best condition by

changing the amount of air flow. It is designed to respond quickly

to temperature that changes every second, such as high speed driving

and traffic congestion, and to change a fan speed continuously. It

reduces a fanning noise while it suppresses power and decreases mpg,

and it contributes to having a comfortable driving

environment.

A fan clutch controls the

rotation of a fan because it reacts to the temperature of air which

passes through the radiator and has the role to maintain the heat

balance of an engine cooling system at the best condition by

changing the amount of air flow. It is designed to respond quickly

to temperature that changes every second, such as high speed driving

and traffic congestion, and to change a fan speed continuously. It

reduces a fanning noise while it suppresses power and decreases mpg,

and it contributes to having a comfortable driving

environment.

Structure

The rotation force of the fan is transmitted through the silicone oil inside the fan clutch driven by the belt and the rotation of the engine which is the principal source of power. This silicone oil has a highly stable density.

By a large amount of silicone oil in the working chamber the fan speed increases when the atmosphere's temperature is high. Conversely, when the temperature is low, a small amount of silicone oil is regulated into the chamber and the fan speed slows down. It has a structure of adjusting heat balance of engine.

The rotation force of the fan is transmitted through the silicone oil inside the fan clutch driven by the belt and the rotation of the engine which is the principal source of power. This silicone oil has a highly stable density.

By a large amount of silicone oil in the working chamber the fan speed increases when the atmosphere's temperature is high. Conversely, when the temperature is low, a small amount of silicone oil is regulated into the chamber and the fan speed slows down. It has a structure of adjusting heat balance of engine.

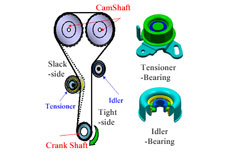

Feature

This bearing is located in the front of an internal combustion engine. It provides tension to the belt which drives from the crankshaft, to the cam shaft, alternator, air compressor, power steering pump, and water pump. It must handle high temperatures, high-speed rotation, and belt vibration because of contiguity in the engine used in order to make the direction of a belt change. These bearings are designed against different specification from normal deep groove bearings. These bearing are divided roughly into two types and identified by the usage, respectively.

This bearing is located in the front of an internal combustion engine. It provides tension to the belt which drives from the crankshaft, to the cam shaft, alternator, air compressor, power steering pump, and water pump. It must handle high temperatures, high-speed rotation, and belt vibration because of contiguity in the engine used in order to make the direction of a belt change. These bearings are designed against different specification from normal deep groove bearings. These bearing are divided roughly into two types and identified by the usage, respectively.

1. Tensioner bearing: Bearing which applies tension to the drive belt, and prevents slack.

2. Idler bearing: Bearing which affects a

change in the angle of direction which a belt runs or to adjust

contact width with a pulley.

Structure

Sealed groove bearing is usually used and it also has built-in heat-resistant grease, a seal, and retainer and the structure can withstand a temperature change or change of belt tension when the car is running.

Sealed groove bearing is usually used and it also has built-in heat-resistant grease, a seal, and retainer and the structure can withstand a temperature change or change of belt tension when the car is running.

1. Tensioner bearing: The rotation center is movable in order to give tension to the belt.

2. Idler Bearing: Unitized with the pulley.

Product function

The following are important functions of these indispensable parts for the smooth drive of the belt system.

1. To add initial tension by using the pivot hole and eccentric hole which absorb tension changes in the timing belt where the temperature changes when the engine is running.

2. To prevent any belt-skip, which would cause mis-matching of the valve timing between crank shaft and cam shaft.

Feature

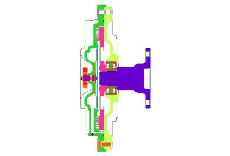

This type of water pump

bearing is mainly used in automotive engine. Grease-contained double

race unitized construction enables the shaft to enlarge the

diameter, then consequently to increase the load capacity of the

bearing. The shaft which is a inner race at the same time is longer

than outer race and carries and holds a impeller and

flange/pulley.

This type of water pump

bearing is mainly used in automotive engine. Grease-contained double

race unitized construction enables the shaft to enlarge the

diameter, then consequently to increase the load capacity of the

bearing. The shaft which is a inner race at the same time is longer

than outer race and carries and holds a impeller and

flange/pulley.

Structure

Market demand is trending towards the 10 year/100,000-mile guarantee as time progresses and pump failures are more noticeable as engines last longer. When we investigate a defective pump after usage, we can find the following potential causes of early degradation of the bearing - sealing defect (water invasion), breakage, an unsuitable clearance value, faulty load (too tight tension on pulley drive), the slipping effect of a partial load (too loose tension on pulley drive), foreign substances mixing from the outside, overheating occurring from vibration and other external factors, etc., unusual wear, and flaking of bearing. The Ball track of the bearing must guide the balls in as perfect an orbit as possible to rotate smoothly and normally. Also, even if each part's tolerance accuracy is matched and maintained, an orbital side loading usually acts as the maximum weak point, and subsequently will lead to degradation damage which results in an orbital imbalance between the drive pulley and rollers. We improve the degree of purity by washing each part thoroughly before assembly which is then carried out by an automated machine to apply the exact charge of grease and fit the oil seal before a 100% test releases the bearing for use. Such manufacturing precision improves the life and guarantees the stability of the bearing and is carefully detailed in the drawings and standards laid down by GMB.

Market demand is trending towards the 10 year/100,000-mile guarantee as time progresses and pump failures are more noticeable as engines last longer. When we investigate a defective pump after usage, we can find the following potential causes of early degradation of the bearing - sealing defect (water invasion), breakage, an unsuitable clearance value, faulty load (too tight tension on pulley drive), the slipping effect of a partial load (too loose tension on pulley drive), foreign substances mixing from the outside, overheating occurring from vibration and other external factors, etc., unusual wear, and flaking of bearing. The Ball track of the bearing must guide the balls in as perfect an orbit as possible to rotate smoothly and normally. Also, even if each part's tolerance accuracy is matched and maintained, an orbital side loading usually acts as the maximum weak point, and subsequently will lead to degradation damage which results in an orbital imbalance between the drive pulley and rollers. We improve the degree of purity by washing each part thoroughly before assembly which is then carried out by an automated machine to apply the exact charge of grease and fit the oil seal before a 100% test releases the bearing for use. Such manufacturing precision improves the life and guarantees the stability of the bearing and is carefully detailed in the drawings and standards laid down by GMB.

Feature

Suspension parts are fitted

in order to ease the external force and absorb the bounce of wheel

by spring for adjusting ride height as well as more comfortable

ride.

Suspension parts are fitted

in order to ease the external force and absorb the bounce of wheel

by spring for adjusting ride height as well as more comfortable

ride.

Car body and wheels are linked by springs and steering

linkages such as suspension arms and more.

Ball joint is one of

the most important suspension parts which is used for not only

linkages between car body and wheels but also fills the role of

pivot on turning the steering wheel.

Structure

GMB Ball Joints are designed in order to correspond to the loading

against all directions as running, cowering and braking by using

sphere ball stud, which is retained by resinous ball sheet for

maintenance free.

GMB Ball Joints are designed in order to correspond to the loading

against all directions as running, cowering and braking by using

sphere ball stud, which is retained by resinous ball sheet for

maintenance free.

We build them with a cold formed, heat-treated stud for superior strength and durability. Despite you do not need to grease them up as a normal use, grease lube is attached to satisfy the customer's needs.

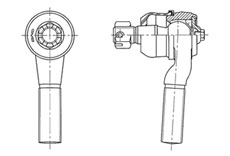

Feature

Tie-rods are one of the center pieces of a Vehicle's chassis system which turns a direction

of Vehicle via steering wheel.

Tie-rods are one of the center pieces of a Vehicle's chassis system which turns a direction

of Vehicle via steering wheel.

Turning steering wheel transmits

the torque to the steering gear through the column shaft and

steering joints.

The torque which is converted into

reciprocating motion on the steering gear turns the direction of

wheels via tie-rod ends and steering knuckles.

Tie-rod ends are

a kind of ball joints which link the steering gear and knuckles,

commonly fitted at both ends of tie-rod.

There are 2 different

kinds of tie-rods fitted to both right / left wheel that depend on

the type of steering gear.

Recirculation ball nut type gear uses

2 tie-rod ends at both ends and rack / pinion type gear uses a

tie-rod end to the gear side, also a rack end to the steering

knuckle side.

Structure

The

schematic design of GMB tie-rod ends are as same as our ball joints

except it connected to the housing by screw thread for adjusting

alignment. Also, the ball joint of rack end is coated by dust cover

for maintenance free. The

schematic design of GMB tie-rod ends are as same as our ball joints

except it connected to the housing by screw thread for adjusting

alignment. Also, the ball joint of rack end is coated by dust cover

for maintenance free.

|

|

|

29.11.2007

Himeji Daiichi Kogyo Co., Ltd company has issued supplement No.009-1 to the existing catalogue of

production Vol.11.

Details01.11.2007

GMB Corporation company published bulletin of new production No.025.

Details01.10.2007

GMB Corporation company published bulletin of new production No.025.

Details01.09.2007

GMB Corporation company published bulletin of new production No.023.

Details01.08.2007

GMB Corporation company published bulletin of new production No.022.

Details01.07.2007

GMB Corporation company published bulletin of new production No.021.

Details01.06.2007

GMB Corporation company published bulletin of new production No.020.

Details01.05.2007

GMB Corporation company published bulletin of new production No.019.

Details01.04.2007

GMB Corporation company published bulletin of new production No.018.

Details01.03.2007

GMB Corporation company published bulletin of new production No.017.

Details01.02.2007

GMB Corporation company published bulletin of new production No.016.

Details01.01.2007

GMB Corporation company published bulletin of new production No.015.

Details12.05.2006

Himeji Daiichi Kogyo Co., Ltd company has issued supplement No.006 to the existing catalogue of

production Vol.10.

Details11.04.2006

Himeji Daiichi Kogyo Co., Ltd company has issued supplement No.007 to the existing catalogue of production Vol.10.

Details26.02.2006

Himeji Daiichi Kogyo Co., Ltd company has issued supplement No.006-4 to the existing catalogue of

production Vol.10.

Details28.01.2006

Eiken Industries Co., Ltd company has issued the new catalogue for 2006.

Details

19.01.2006

Himeji Daiichi Kogyo Co., Ltd company has issued supplement No.009-1 to the existing catalogue of

production Vol.10.

Details |

|

|