|

Ðóññêèé |

|

Articles

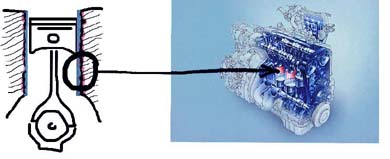

Metal-ceramic cover.

Starting from 1999 our company applies technology NIOD and makes practical researches in friction control area and as a result with the premature deterioration of work faces accompanying it, which has directly proportional relation to decrease of technical characteristics of units during their operation. Tribotechnical composition NIOD (directional ionic diffusion) is a principle new technology which allows increasing in some times working resource of rubbed metal parts and units of your car. The technology applying allows to compensate already available deterioration, to protect friction surfaces and to recover a normal unit operation without their disassembly and overhaul in a mode of regular operation. NIOD - is a small-dispersion multi-component dry mixture on the basis of inorganic compounds, principal components of composition are silicon dioxide and magnesium oxide. The designed technology is based on formation on rubbing metal practically ideally smooth metal-ceramic cover through formation on them of servowitte skin of NIOD tribotechnical composition tape. It happens in conditions of high pressure, friction and micro contact high temperature during the mechanic influence upon NIOD. The components of tribotechnical composition diffuse in surface layer of steel, and during processing makes on its surface a steady ceramic cover. The formed cover keeps on the steel surface plastically and firmly until it flows through to excessive loadings. Coefficients of temperature linear expansion of a cover on the basis of NIOD and steel are proportional what is very important at operation of blocks and mechanisms in conditions of high temperatures. Saturated layer of metal and a cover became thicker during exploitation, select clearances and thus compensate the output. The cover is growing exclusively in those places where friction and high temperature are present, and is equal in such quantity (that is on the ground of introduction dose) which provides the most smoothness of surface and perfect thermal clearance between them in view of unit exploitation real mode.  As a result of processing the unit by NIOD the rubbed surfaces contacting in pair acquire unique tribotechnical properties which promotes friction coefficient 5-10 times decreasing in pairs steel - steel, steel - cast iron, steel - bronze, steel - aluminum. In special situations this fact will allow the processed units absolute without lubrication, which is typifying to morning engine starting up or long-time work, both the engine, and transmission in conditions of low temperatures. As the result of processing temperature of bearing blocks is reduced in 2~3 times, worm gear in 2,5~5 times, heating of gear teeth is practically stopped. The general decrease of energy consumption is observed at increase of efficiency. This technology applying in many cases* will allow you to avoid an overhaul and thus to save sizeable means in your budget. The described technology is patented in Russia and has ?The Certificate of Recognition? in Ukraine. There has been gained certain experience, which allows to objectively confirming the effectiveness of the new method in comparison with traditional repairs. Preventive processing of units by NIOD allows to prolong the term of your engine serving, to reduce a fuel consumption, to increase the power, to raise compression up to nominal sizes, to improve dynamic parameters of your car, to decrease noisiness, to reduce an oil consumption, to facilitate start of the engine, to decrease exhaust opacity and vibration. The complete processing of cars allows to reduce expenses for their operation and service in 1,5~2 times and to prevent their irreversible destruction in breakdown situations, connected with losses of lubrication and a cooling fluid. .  In order to make processing of your unit** will not required it's dismantling and taking apart. It is necessary only to provide access of certain quantity of composition NIOD up to rubbing surfaces and to prolong operation of unit at a usual mode during some control time. With this period completed executed certain technological works and your unit is ready to work again. Use the proved and cheaper repairs method, which became possible as a result of introduction of new technologies and scientific achievements of the end of XX century. The technology NIOD is protected by: ÒÓ 0254-002-23124986-96, patent No.2057257, patent No.2035636, the Conformance Certificate No. POCC RU.HX18. H00085, Sanitary-and-Epidemiologic Conclusion No.47.01.02.025 P.000652.05.01, the Certificate for Brand No.147560, the Conclusion of Odessa Regional Chamber of Commerce and Industry No.ÍÏ27, the Act ÂÍÈÈÏÎ No.113/562 and some more of the state documents showing its unique kind. * Application of technology NIOD for transmissions with a residual resource less than 25%, of the destroyed bearings or of gear teeth, and also for internal combustion engines with a residual resource less than 25%, destroyed or completely worn out piston rings, the broken bearings and the destroyed pistons is inexpedient. ** Units which have been exploited with oil, containing Rimet, Fial, Forsan, Lubrifil, EP type?s nozzles and analogical types can't be processed with NIOD. |

|

Designed by SevenStyles and Rusaln Rusanov |